Our cooling plates from the standard series or developed individually provide professional thermal management for electric vehicles, power electronics as well as gastronomy and medical technology.

Thermal management for electric mobility & laboratory technology

Cooling plates: Standard series or made to specification

Our Costumers

- E-mobility, hybrid drives, fuel cells

- Power electronics & Battery cooling

- Gastronomy

- Medical technology & Laboratory technology

Product Overview

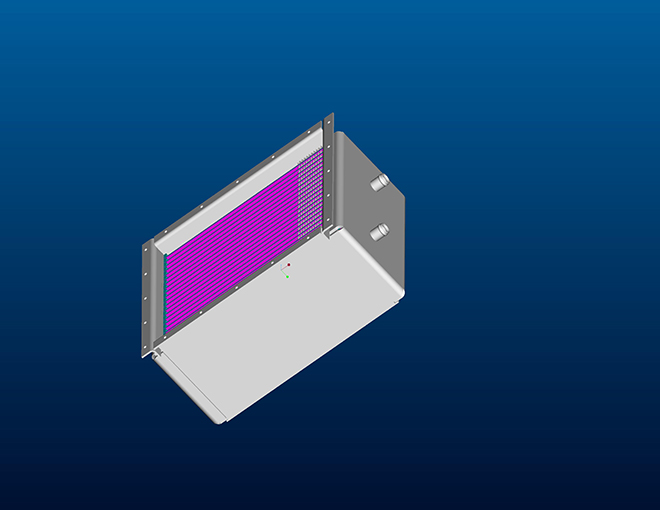

Accumulator/ battery cooling

Significant experience has been gained in various development projects in the area of cooling plates, especially for battery cooling and inverter cooling. Different geometries and design principles have been realized.

We are currently developing a modular system with staggered sizes in order to be able to react quickly and cost-effectively to customer requirements. The range of applications is very diverse from automotive to computer technology, gastronomy, laboratory technology, medicine, process technology, rail vehicles to inverters …

Latent heat storage / energy storage

As part of the qOpt research project of the Forschungsgesellschaft Kraftfahrwesen Aachen (fka) as consortium leader and with HAUGG as industrial partner, the model of a latent heat storage system was developed and measured in tests.

The aim of the project is to develop a latent heat storage system in combination with an intelligent operating strategy for waste heat recovery. Some advantages:

Increased range of an electric vehicle

Storage of lost energy and subsequent on-demand supply

Increasing the overall efficiency of an electric vehicle.

Low temperature cooling system / water cooler

As part of the KERME research project, HAUGG, as an industrial partner, designed the cooling circuit for an electric motor developed at Aachen University and supplied the components. The project partners were the WZL (Machine Tool Laboratory) and the IEM (Institute for Electrical Machines) of RWTH Aachen University. The goal of the project was the development of a scalable and modular electric motor for different power levels with an optimised cooling circuit.

Cooling of power electronics

With any power electronics, heat means a loss of power. In order to optimize these losses, active cooling is a good solution.

Experiences from Formula Student applications brought the first concrete measured values, which were subsequently verified.

The fields of application are manifold, so that we gain knowledge with each new project.

Our service

HAUGG Group Service

HAUGG produces and delivers the necessary air conditioning parts, radiators and radiator grids as custom-made products within 24 hours. This service not only benefits specialist workshops and automotive parts dealers, but also the spare parts service for our OE customers.